Orbital Arc Welding Machine

Introduction

Full Position Automatic Welding Machine/Pipe All-Position Hot Wire Argon Arc Welding Machine/Arbital Arc Welding Machine

- It adopts the welding method of fixing the weldment and rotating the welding gun driven by the permanent magnet wheel adsorption on the outer circle of the welding parts.

- Suitable for tube – tube circular seam welding

- Suitable for carbon steel, alloy steel and other magnetic metal or stainless steel and other non-magnetic metal (optional rail) material welding

- Welding mode is argon arc welding, stable welding parameters, high adjustment accuracy. Main body of machine head adopts high strength aluminum alloy material, light structure

- Equipped with wireless remote control controller, convenient for real-time control and adjustment in the welding process

- Eight section welding interval parameter programming, easy to control all position welding depth and wire filling amount. The whole machine integrated design, compact structure, mature and reliable; Magnetic adsorption is stable and reliable, and the preparation time before welding is short

- The welding gun can be adjusted in the radial, axial and welding gun Angle to ensure the multi-position and multi-angle conversion of the welding gun

- CNC automatic wire feeding machine design, with automatic backdrawing function and pulsating wire feeding function, wire feeding precision is high

- Control system adopts large touch screen man-machine interface, convenient programming

- Welding program storage is 30 sets, corresponding welding programs can be recalled according to the specification of welding parts

- Standard swing system (OSC) arc length tracking system (AVC), to ensure the stability of the welding process, beautiful shape

- Forced circulation water cooling system ensures long time reliable operation of the whole machine

- One-button operation, automatic completion of the whole welding process; Welding parameters can also be manually interfered in real time as required

Model

GW160T

Welding outer diameter

>159mm

Pipe length

>400mm

Pipe thickness

>5mm

Axle track

215mm

wheelbase

115mm

Welding power

Panasonic YC-400TX

Supply power

Welder 30KW/380V/50HZ

Controller

1KW/220V/50HZ

Rotate speed

0.3rpm-1.5rpm

Welding gun

LS22 type water cooled argon arc welding torch

Welding gun adjustable angle

0-90°

Cooling mode

Forced internal circulation, cooling medium antifreeze, volume 9.0L. Cooling capacity1.5KW(1L/min)

Controller

Color touch screen controller

Storage

30 sets of welding process

Welding layers

Automatic layering

Welding torch wiggler

Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s

Arc length tracker

Tracking range0-20mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm

Wire feeder

wire diameter1.0mm, 5KG/roller

Overall size

410mm*450mm*230mm(L*W*H)

Weight

About 30KG

Video

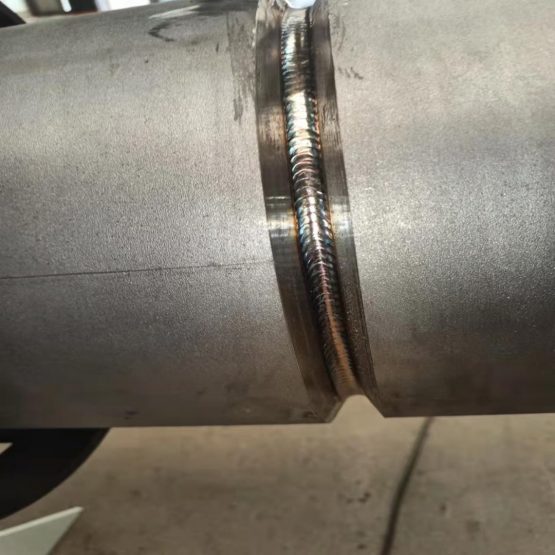

Gallery

Introduction

Full Position Automatic Welding Machine/Pipe All-Position Hot Wire Argon Arc Welding Machine/Arbital Arc Welding Machine

- It adopts the welding method of fixing the weldment and rotating the welding gun driven by the permanent magnet wheel adsorption on the outer circle of the welding parts.

- Suitable for tube – tube circular seam welding

- Suitable for carbon steel, alloy steel and other magnetic metal or stainless steel and other non-magnetic metal (optional rail) material welding

- Welding mode is argon arc welding, stable welding parameters, high adjustment accuracy. Main body of machine head adopts high strength aluminum alloy material, light structure

- Equipped with wireless remote control controller, convenient for real-time control and adjustment in the welding process

- Eight section welding interval parameter programming, easy to control all position welding depth and wire filling amount. The whole machine integrated design, compact structure, mature and reliable; Magnetic adsorption is stable and reliable, and the preparation time before welding is short

- The welding gun can be adjusted in the radial, axial and welding gun Angle to ensure the multi-position and multi-angle conversion of the welding gun

- CNC automatic wire feeding machine design, with automatic backdrawing function and pulsating wire feeding function, wire feeding precision is high

- Control system adopts large touch screen man-machine interface, convenient programming

- Welding program storage is 30 sets, corresponding welding programs can be recalled according to the specification of welding parts

- Standard swing system (OSC) arc length tracking system (AVC), to ensure the stability of the welding process, beautiful shape

- Forced circulation water cooling system ensures long time reliable operation of the whole machine

- One-button operation, automatic completion of the whole welding process; Welding parameters can also be manually interfered in real time as required

| Model | GW160T |

| Welding outer diameter | >159mm |

| Pipe length | >400mm |

| Pipe thickness | >5mm |

| Axle track | 215mm |

| wheelbase | 115mm |

| Welding power | Panasonic YC-400TX |

| Supply power | Welder 30KW/380V/50HZ |

| Controller | 1KW/220V/50HZ |

| Rotate speed | 0.3rpm-1.5rpm |

| Welding gun | LS22 type water cooled argon arc welding torch |

| Welding gun adjustable angle | 0-90° |

| Cooling mode | Forced internal circulation, cooling medium antifreeze, volume 9.0L. Cooling capacity1.5KW(1L/min) |

| Controller | Color touch screen controller |

| Storage | 30 sets of welding process |

| Welding layers | Automatic layering |

| Welding torch wiggler | Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s |

| Arc length tracker | Tracking range0-20mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm |

| Wire feeder | wire diameter1.0mm, 5KG/roller |

| Overall size | 410mm*450mm*230mm(L*W*H) |

| Weight | About 30KG |