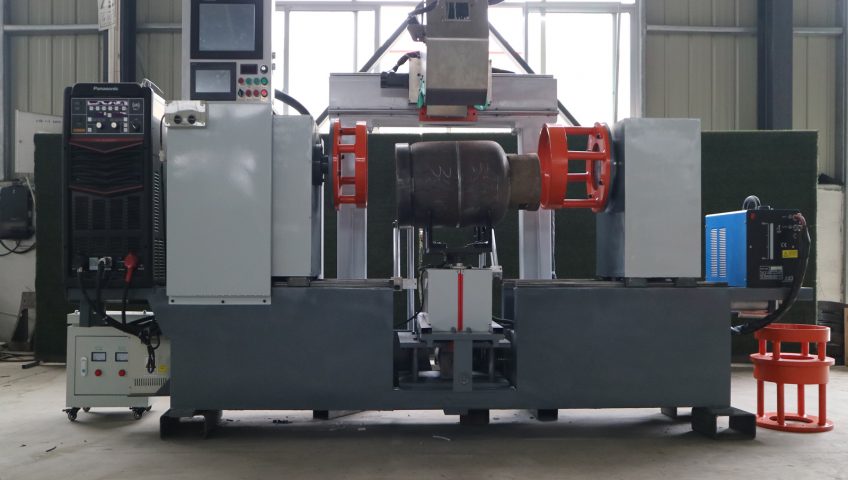

Fully Automatic Air Compressor Tanks Circumferential Welding Machine

Introduction

SINGLE HEAD CIRCUMFERENTIAL WELDING MACHINE

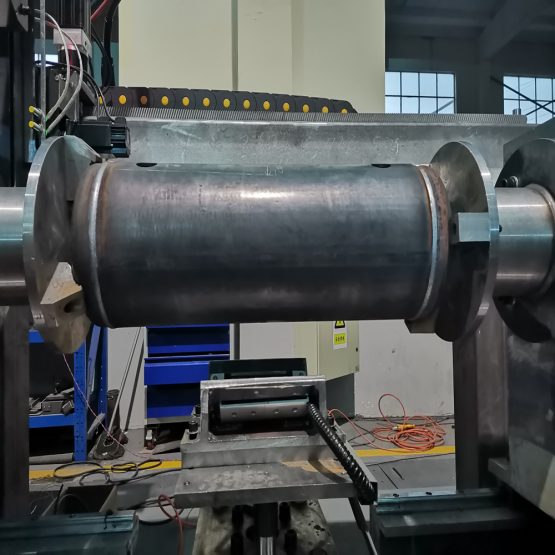

This circumferential welding machine is suitable for all kinds of Cylinder, such as LPG Cylinder, Air pressure Tank, LNG Tank, Water tanks.Detailed Information Of CIrcumferencial Welding Machine for Air Pressure Tanks

3-part cylinder: Thickness:2MM; Air tank length range:700-1000mm

Item

Description

Qnty.

Remarks

1

Hoist machine for cylinder circumferential welding machine

1

Main machine rack

1

Welded frame structure

Spindle power box

1

Ac motor + reducer

tailstock box

1

Workpiece holding mechanism

Lifting bracket

1

Bracket lifting air cylinder

Welding head X moving mechanism

1

X and Y axis moving mechanism of welding torch

1

Welding torch assembly

1

2

Welding system

1

MIG Welding source and integration

1

Panasonic 500GS5

Wire feeder and controller

1

Panasonic

Welding torch

1

Circulation cooling tank

1

Welding torch cooling

Equipment input capacity

35KVA

voltage (three phase)

380V 50Hz

Pneumatic system working pressure

0.5~0.7MPa

3

Laser tracker

1

Automatic tracking of welding seam position

4

Electric control system

1

PLC+Color touch screen HMI

Omron or Mitsubish

5

Package

1

Steel base

Tracking laser system

- The power of this machine is 1000W.

- it can adapt to track the left and right distance 30mm, up or down 30mm, or customize special needs.

- The tracking speed is in line with the speed requirement of ring welding, or greater than 2 m/min.

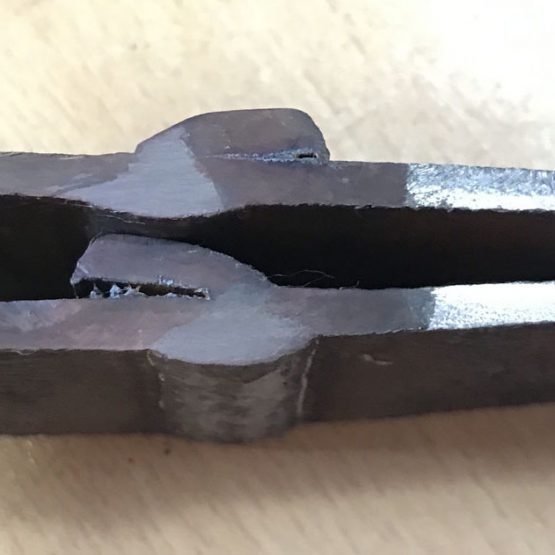

- It is suitable for lap or splice welding with weld more than 1mm. The width of the corner weld seam is not limited.

- Recognition accuracy: 0.5mm

- The response speed of weld recognition: 0.2S.

- Support welding speed: 0~2000mm/min

- Support welding types: gas shielded arc welding, argon arc welding, plasma welding and laser welding.

The whole system including computer, industrial camera, laser line, X/Y adjusting mechanism, hood, software etc.

Video

Gallery

Introduction

SINGLE HEAD CIRCUMFERENTIAL WELDING MACHINE

This circumferential welding machine is suitable for all kinds of Cylinder, such as LPG Cylinder, Air pressure Tank, LNG Tank, Water tanks.Detailed Information Of CIrcumferencial Welding Machine for Air Pressure Tanks

3-part cylinder: Thickness:2MM; Air tank length range:700-1000mm

| Item | Description | Qnty. | Remarks |

| 1 | Hoist machine for cylinder circumferential welding machine | 1 | |

| Main machine rack | 1 | Welded frame structure | |

| Spindle power box | 1 | Ac motor + reducer | |

| tailstock box | 1 | Workpiece holding mechanism | |

| Lifting bracket | 1 | Bracket lifting air cylinder | |

| Welding head X moving mechanism | 1 | ||

| X and Y axis moving mechanism of welding torch | 1 | ||

| Welding torch assembly | 1 | ||

| 2 | Welding system | 1 | |

| MIG Welding source and integration | 1 | Panasonic 500GS5 | |

| Wire feeder and controller | 1 | Panasonic | |

| Welding torch | 1 | ||

| Circulation cooling tank | 1 | Welding torch cooling | |

| Equipment input capacity | 35KVA | ||

| voltage (three phase) | 380V 50Hz | ||

| Pneumatic system working pressure | 0.5~0.7MPa | ||

| 3 | Laser tracker | 1 | Automatic tracking of welding seam position |

| 4 | Electric control system | 1 | PLC+Color touch screen HMI

Omron or Mitsubish |

| 5 | Package | 1 | Steel base |

Tracking laser system

- The power of this machine is 1000W.

- it can adapt to track the left and right distance 30mm, up or down 30mm, or customize special needs.

- The tracking speed is in line with the speed requirement of ring welding, or greater than 2 m/min.

- It is suitable for lap or splice welding with weld more than 1mm. The width of the corner weld seam is not limited.

- Recognition accuracy: 0.5mm

- The response speed of weld recognition: 0.2S.

- Support welding speed: 0~2000mm/min

- Support welding types: gas shielded arc welding, argon arc welding, plasma welding and laser welding.

The whole system including computer, industrial camera, laser line, X/Y adjusting mechanism, hood, software etc.