Automatic Double End Flange Welding Machine

Introduction

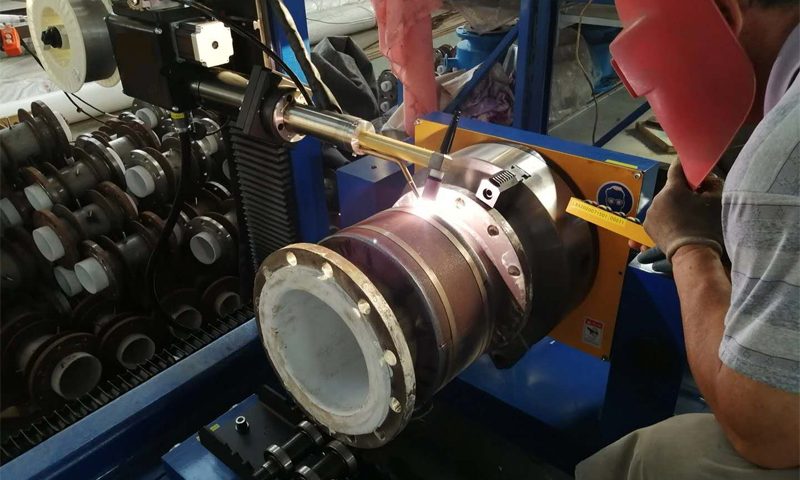

Automatic Double End Flange Welding Machine

- It is suitable for pipe with double flange internal and external girth weld fillet

- Suitable for welding of carbon steel, low alloy steel, stainless steel and other materials

- It can be equipped with argon arc welding, secondary arc welding, MIG / MAG welding, plasma welding and other welding equipment

- Integrated design of the whole machine, compact structure; Unique grooved wheel design, accurate rotation and positioning, fast loading and unloading

- Control system adopts large touch screen man-machine interface, convenient for programming

- The storage capacity of welding process is 30 sets, and the corresponding welding process can be called directly according to the number of weldment specification

- Arc length tracking system (AVC) and welding gun yaw system (OSC) are provided as standard

- CNC automatic wire feeder, with automatic reverse drawing function and pulse wire feeding function, with high wire feeding accuracy

- One button operation to automatically complete the whole welding process; Welding parameters can also be interfered in real time as required

Model

GW600

Welding outer diameter

150-600mm

Pipe length

800mm

Pipe thickness

>1mm

Welding power

MIG/NBC500;WSM400

Supply power

Welder 30KW/380V/50HZ

Controller

0.5KW/220V/50HZ

Controller

Color touch screen controller

Storage

30 sets of welding process

Welding layers

Automatic layering

Welding torch wiggler

Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s

Arc length tracker

Tracking range0-20mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm

Wire feeder

wire diameter1.0mm, 5KG/roller

Overall size

200mm*210mm*2400mm(L*W*H)

Weight

About 1000KG

Video

Gallery

Introduction

Automatic Double End Flange Welding Machine

- It is suitable for pipe with double flange internal and external girth weld fillet

- Suitable for welding of carbon steel, low alloy steel, stainless steel and other materials

- It can be equipped with argon arc welding, secondary arc welding, MIG / MAG welding, plasma welding and other welding equipment

- Integrated design of the whole machine, compact structure; Unique grooved wheel design, accurate rotation and positioning, fast loading and unloading

- Control system adopts large touch screen man-machine interface, convenient for programming

- The storage capacity of welding process is 30 sets, and the corresponding welding process can be called directly according to the number of weldment specification

- Arc length tracking system (AVC) and welding gun yaw system (OSC) are provided as standard

- CNC automatic wire feeder, with automatic reverse drawing function and pulse wire feeding function, with high wire feeding accuracy

- One button operation to automatically complete the whole welding process; Welding parameters can also be interfered in real time as required

| Model | GW600 |

| Welding outer diameter | 150-600mm |

| Pipe length | 800mm |

| Pipe thickness | >1mm |

| Welding power | MIG/NBC500;WSM400 |

| Supply power | Welder 30KW/380V/50HZ |

| Controller | 0.5KW/220V/50HZ |

| Controller | Color touch screen controller |

| Storage | 30 sets of welding process |

| Welding layers | Automatic layering |

| Welding torch wiggler | Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s |

| Arc length tracker | Tracking range0-20mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm |

| Wire feeder | wire diameter1.0mm, 5KG/roller |

| Overall size | 200mm*210mm*2400mm(L*W*H) |

| Weight | About 1000KG |