Auto. Steel Bar Rolling and Cutting Machine

Introduction

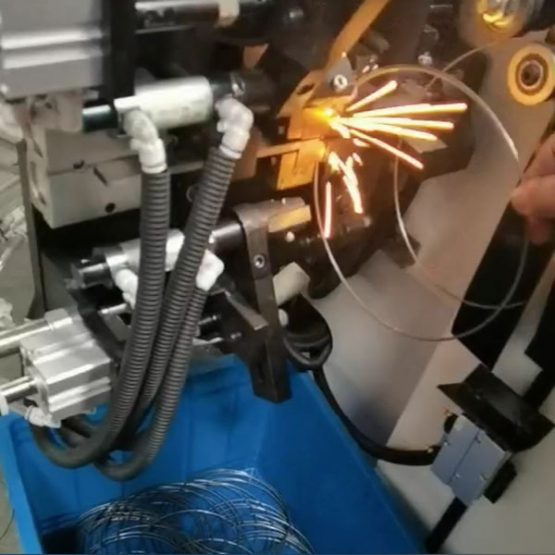

Auto. Steel Bar Rolling and Cutting Machine

1.Characters:

Auto. NC controlled hydraulic rolling, automatically achieves process of straight wire, feeding wire, rolling, forming and cutting, recording the quantity. With functions of output setting, auto, control, wire withdrawal…. The wire can be withdrawn and recoiled during the machine is under adjustment, which greatly reduces the waste of wire. It has features of compatible, low noise, digital control; stable running, high production speed, manual and auto.modes switch……

Application: Suitable for various metal wires (round, flat, square, hexagonal, etc.) such as steel wire, iron wire, aluminum wire, stainless steel wire, etc.

2.Technical Parameters:

Steel bar range: 10-16MM

Motor power: 11Kw

Weight: 950Kgs

Voltage: 380V, 50Hz

Mould: Adopts skD11 heat treatment, above HRC58

Max. flow: 230

Number of rotation axis: 5 axis with up and down rotation

Control mode: SCM

Process steps: feeding, drawing, pressing, forming, rolling, cutting, auto dropping

Machine working style: vertical

Check counter: P4AR-1000 pulse

Servo control

Dimensions: 2350mm*850*1680mm

Electrical components: Mitsubishi or Omron

Video

Gallery

Introduction

Auto. Steel Bar Rolling and Cutting Machine

1.Characters:

Auto. NC controlled hydraulic rolling, automatically achieves process of straight wire, feeding wire, rolling, forming and cutting, recording the quantity. With functions of output setting, auto, control, wire withdrawal…. The wire can be withdrawn and recoiled during the machine is under adjustment, which greatly reduces the waste of wire. It has features of compatible, low noise, digital control; stable running, high production speed, manual and auto.modes switch……

Application: Suitable for various metal wires (round, flat, square, hexagonal, etc.) such as steel wire, iron wire, aluminum wire, stainless steel wire, etc.

2.Technical Parameters:

Steel bar range: 10-16MM

Motor power: 11Kw

Weight: 950Kgs

Voltage: 380V, 50Hz

Mould: Adopts skD11 heat treatment, above HRC58

Max. flow: 230

Number of rotation axis: 5 axis with up and down rotation

Control mode: SCM

Process steps: feeding, drawing, pressing, forming, rolling, cutting, auto dropping

Machine working style: vertical

Check counter: P4AR-1000 pulse

Servo control

Dimensions: 2350mm*850*1680mm

Electrical components: Mitsubishi or Omron