Pipe-Pipe/Pipe-Flange/Flange-Elbow Automatic Welding Machine

Introduction

Pipe-Pipe/Pipe-Flange/Flange-Elbow Automatic Welding Machine

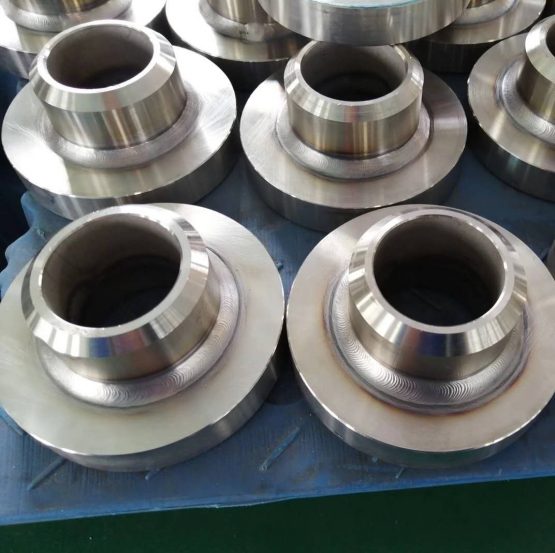

- Suitable for pipe and pipe, pipe and elbow, three-way pipe, pipe and deep neck butt joint; pipe and flange, elbow and flange angle connection

- Suitable for welding of carbon steel, low alloy steel, stainless steel,aluminum and copper

- It can be equipped with argon arc welding, secondary welding, MIG / MAG welding, plasma welding and other welding equipment

- Integrated design of the whole machine, compact structure, mature and reliable; accurate rotation and positioning of three- claw self- centering chuck.

- Three dimensional welding operation arm + full angle positioned + welding gun angle adjusting mechanism ensures multi position and multi angle conversion of welding gun

- he control system adopts large screen man-machine interface, convenient programming

- he storage capacity of welding process is 30 sets, and the corresponding welding process can be called directly according to the specification and number of welding parts

- Standard arc length tracking system (AVC) and welding torch pendulum system (OSC)

- CNC automatic wire feeding machine, with automatic reverse wire drawing function and pulsating wire feeding function, wire feeding precision is high

- Forced circulation water cooling system ensures long time reliable operation of the whole machine

- One-button operation, automatic completion of the whole welding process; Welding parameters can also be interfered in real time as required

Model

GW1440T

Welding outer diameter

20-400mm

Pipe length

≤600mm

Pipe thickness

≥1mm

Welding power

WSM400/YC-400TX

Supply power

Welder 30KW/380V/50HZ

Controller

0.5KW/220V/50HZ

Elbow rotation radius

≤300mm

Center diameter of positioner

140mm

Displacement angle

0-360

Cross arm stroke(x/y/z)

800*400*30(manual)

Welding gun adjustable angle

0-90°

Controller

Color touch screen controller

Storage

30 sets of welding process

Welding layers

Automatic layering

Welding torch wiggler

Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s

Arc length tracker

Tracking range0-40mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm

Wire feeder

wire diameter1.0mm, 5KG/roller

Overall size

1300mm*2000mm*1500mm(L*W*H)

Loading weight

240KG

Video

Gallery

Introduction

Pipe-Pipe/Pipe-Flange/Flange-Elbow Automatic Welding Machine

- Suitable for pipe and pipe, pipe and elbow, three-way pipe, pipe and deep neck butt joint; pipe and flange, elbow and flange angle connection

- Suitable for welding of carbon steel, low alloy steel, stainless steel,aluminum and copper

- It can be equipped with argon arc welding, secondary welding, MIG / MAG welding, plasma welding and other welding equipment

- Integrated design of the whole machine, compact structure, mature and reliable; accurate rotation and positioning of three- claw self- centering chuck.

- Three dimensional welding operation arm + full angle positioned + welding gun angle adjusting mechanism ensures multi position and multi angle conversion of welding gun

- he control system adopts large screen man-machine interface, convenient programming

- he storage capacity of welding process is 30 sets, and the corresponding welding process can be called directly according to the specification and number of welding parts

- Standard arc length tracking system (AVC) and welding torch pendulum system (OSC)

- CNC automatic wire feeding machine, with automatic reverse wire drawing function and pulsating wire feeding function, wire feeding precision is high

- Forced circulation water cooling system ensures long time reliable operation of the whole machine

- One-button operation, automatic completion of the whole welding process; Welding parameters can also be interfered in real time as required

| Model | GW1440T |

| Welding outer diameter | 20-400mm |

| Pipe length | ≤600mm |

| Pipe thickness | ≥1mm |

| Welding power | WSM400/YC-400TX |

| Supply power | Welder 30KW/380V/50HZ |

| Controller | 0.5KW/220V/50HZ |

| Elbow rotation radius | ≤300mm |

| Center diameter of positioner | 140mm |

| Displacement angle | 0-360 |

| Cross arm stroke(x/y/z) | 800*400*30(manual) |

| Welding gun adjustable angle | 0-90° |

| Controller | Color touch screen controller |

| Storage | 30 sets of welding process |

| Welding layers | Automatic layering |

| Welding torch wiggler | Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s |

| Arc length tracker | Tracking range0-40mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm |

| Wire feeder | wire diameter1.0mm, 5KG/roller |

| Overall size | 1300mm*2000mm*1500mm(L*W*H) |

| Loading weight | 240KG |