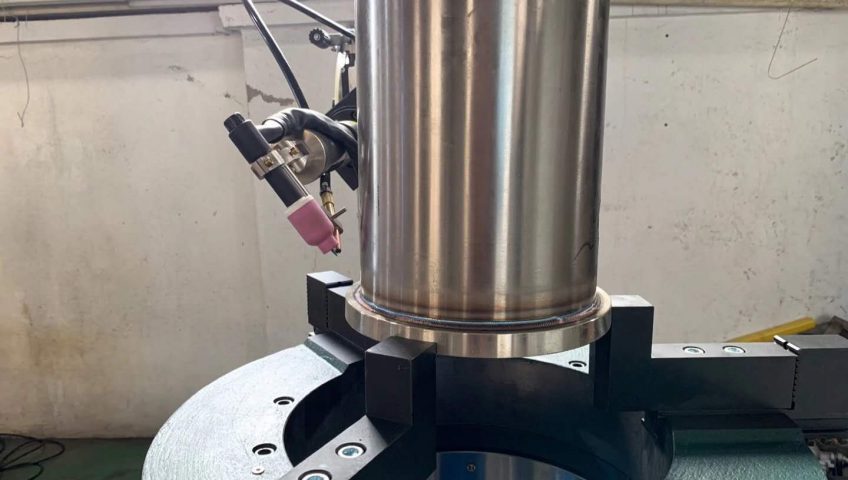

What Should Be Paid Attention To When Welding Flanges And Pipes?

- The flange contact surface should be smooth, annular shallow groove can be allowed, but there shall be no spot scar, sand hole and radiation to the groove, the two flange surface evenly and strictly contact.

- The center line of the flange plane shall be perpendicular to the center line of the pipe, and the deviation shall not be greater than 1-2.5mm.

- Flange screw hole distance position (linear measurement) allowable error 0.5-1.0mm.

- The allowable displacement error between flange hole center line and pipe center line is 1-2mm.

- The allowable deviation of the two flanges is 0.2-0.3mm.

- When welding flange and pipe, attention should be paid to welding stress deformation (especially stainless steel). To ensure the verticality of the flange and the pipeline, avoid two flanges in bolt connection flange parallelism deviation is too large, resulting in gasket clamping and leakage.