1. Introduction:

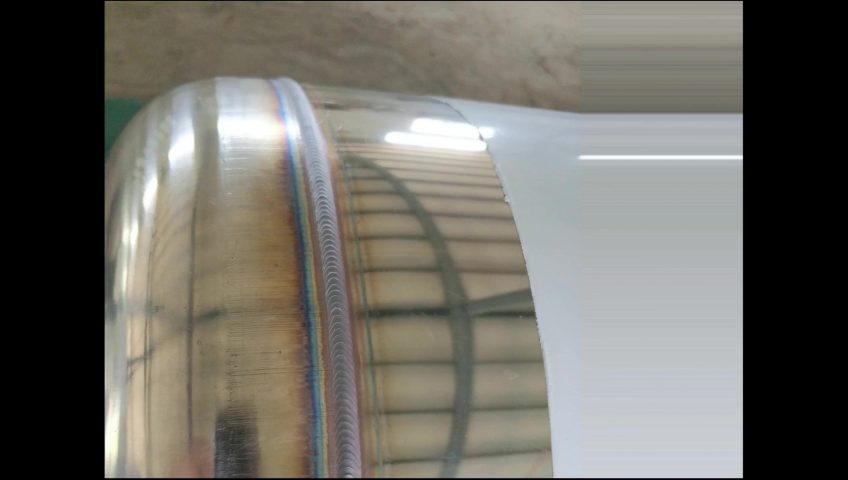

Our system software uses super linear laser to accumulate in the observation position.

At this time, the line laser brightness is greater than the welding arc. Industrial camera input the laser line shape to the computer. Position of weld is obtained by computer analysis and outputted to the actuator to guide or track the correction.

2.Advantages:

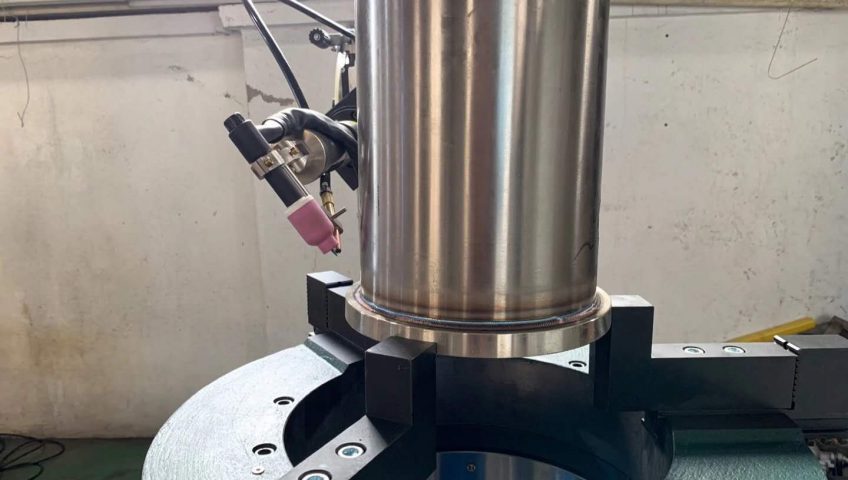

1.It can track both left and right, up and down without touching at the same time, and ensure that the welding position is accurate and the welding current is stable

2.Due to the use of special laser and photo control, it has super strong anti-interference and high stability.

3.The interval between tracking point and welding point is 2cm, real-time tracking.

4. Basically no maintenance required (wipe off the dust or replace the lens cover)

3.Parameter of machine

1. The power of this machine is 1000W.

2. it can adapt to track the left and right distance 30mm, up or down 30mm, or customize special needs.

3. The tracking speed is in line with the speed requirement of ring welding, or greater than 2 m/min.

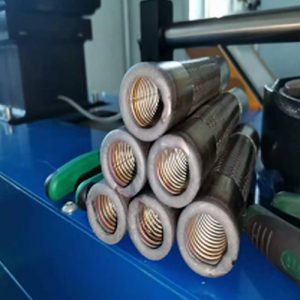

4. It is suitable for lap or splice welding with weld more than 0.2mm. The width of the corner weld seam is not limited.

5. Recognition accuracy: 0.2mm

6. The response speed of weld recognition: 0.2S.

7. Support welding speed: 0~2000mm/min

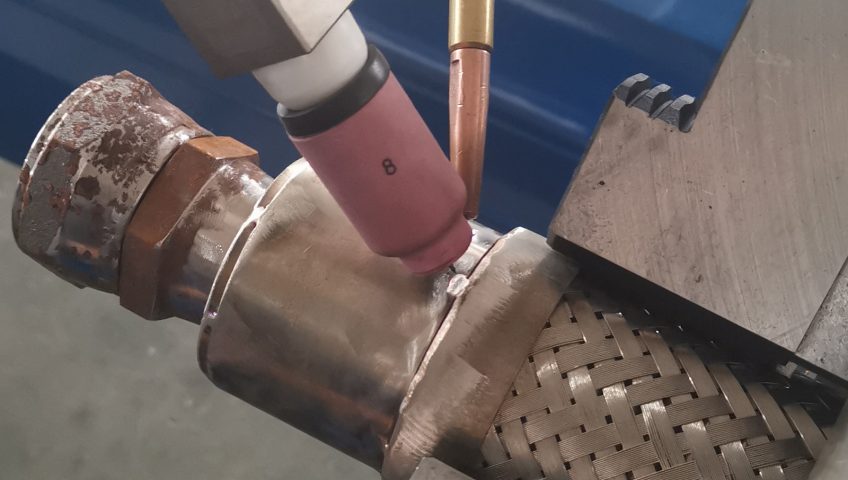

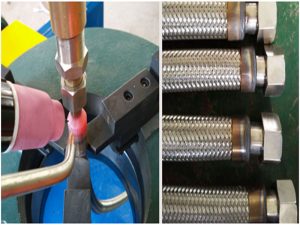

8. Support welding types: gas shielded arc welding, argon arc welding, plasma welding and laser welding.

![]()

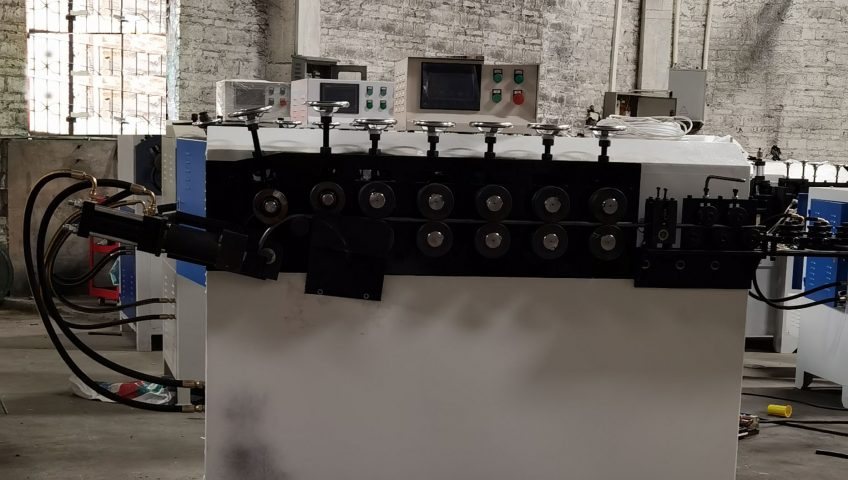

The whole system including computer, industrial camera, laser line, X/Y adjusting mechanism, hood, software etc.

Now, the system is widely used in welding production of stainless steel, sheet metal and process decorative parts as welding seam tracking and guidance.