Tank Circumferencial and Longitudinal Welding Machine

Introduction

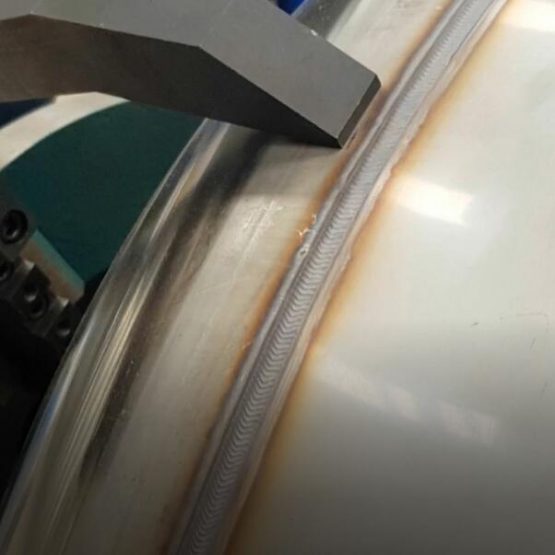

Both Circumferencial and Longitudinal Welding Machine for Large Diameter Tanks

- The welding operation arm is used to cooperate with the CNC roller carrier to drive the workpiece to rotate (circumferential seam welding) and move horizontally (longitudinal seam welding)

- The welding seam between the tank body and the tank body, the flange and the outer corner of the tank body shall be welded at the same time

- Suitable for welding of carbon steel, low alloy steel, stainless steel and other materials

- It can be equipped with argon arc welding equipment

- Integrated design of the whole machine, compact structure, mature and reliable

- Three dimensional welding operation arm + welding gun angle adjustment mechanism to ensure multi position and multi angle conversion of welding gun

- The control system adopts large screen touch screen man-machine interface, which is convenient for programming

- The storage capacity of welding process is 40 sets, and the corresponding welding process can be called directly according to the number according to the weldment specification

- Standard swing system (OSC) and arc length tracking system (AVC)

- CNC automatic wire feeder, with automatic reverse drawing function and pulse wire feeding function, with high wire feeding accuracy

- Water cooling system of the whole machine is reliable and the forced operation time is long

Model

GM3050T

Welding outer diameter

1000-3000

Pipe length

≤5000mm+2times caps

Pipe thickness

3-12mm

Welding power

Panasonic YC-400TX

Supply power

Welder 30KW/380V/50HZ

Controller

1KW/220V/50HZ

Controller

Color touch screen controller

Storage

40 sets of welding program(30sets circular program and 10sets linear program)

Welding layers

Automatic layering

Welding torch wiggler

Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s

Arc length tracker

Tracking range0-40mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm

Wire feeder

wire diameter1.0mm, 5KG/roller

Overall size

8000mm*4000mm*4000mm(L*W*H)

Video

Gallery

Introduction

Both Circumferencial and Longitudinal Welding Machine for Large Diameter Tanks

- The welding operation arm is used to cooperate with the CNC roller carrier to drive the workpiece to rotate (circumferential seam welding) and move horizontally (longitudinal seam welding)

- The welding seam between the tank body and the tank body, the flange and the outer corner of the tank body shall be welded at the same time

- Suitable for welding of carbon steel, low alloy steel, stainless steel and other materials

- It can be equipped with argon arc welding equipment

- Integrated design of the whole machine, compact structure, mature and reliable

- Three dimensional welding operation arm + welding gun angle adjustment mechanism to ensure multi position and multi angle conversion of welding gun

- The control system adopts large screen touch screen man-machine interface, which is convenient for programming

- The storage capacity of welding process is 40 sets, and the corresponding welding process can be called directly according to the number according to the weldment specification

- Standard swing system (OSC) and arc length tracking system (AVC)

- CNC automatic wire feeder, with automatic reverse drawing function and pulse wire feeding function, with high wire feeding accuracy

- Water cooling system of the whole machine is reliable and the forced operation time is long

| Model | GM3050T |

| Welding outer diameter | 1000-3000 |

| Pipe length | ≤5000mm+2times caps |

| Pipe thickness | 3-12mm |

| Welding power | Panasonic YC-400TX |

| Supply power | Welder 30KW/380V/50HZ |

| Controller | 1KW/220V/50HZ |

| Controller | Color touch screen controller |

| Storage | 40 sets of welding program(30sets circular program and 10sets linear program) |

| Welding layers | Automatic layering |

| Welding torch wiggler | Swing range0-20mm, swing speed0-20mm/s, stay time at bevel side 0-5s |

| Arc length tracker | Tracking range0-40mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm |

| Wire feeder | wire diameter1.0mm, 5KG/roller |

| Overall size | 8000mm*4000mm*4000mm(L*W*H) |