Corrugated Metal Sleeve Welder

Introduction

Welding Machine for Corrugated Metal Pipe/Meshy Sleeve and Commpressing Sleeve

Feature

- Welding torch fixed, chuck clamping drive workpiece rotary welding

- Suitable for the welding of bellows, mesh sets and compression sleeves

- Suitable for carbon steel, low alloy steel, stainless steel and other materials of welding

- Adopt tungsten argon arc welding equipment.

- The whole machine integrated design, compact structure, mature and reliable; Three – jaw self – centering chuck accurate rotation and positioning

- CNC automatic wire feeding machine, with automatic reverse wire drawing function and pulsating wire feeding function, wire feeding precision is high

- Control system adopts touch screen man-machine interface, convenient programming

- The welding program storage is 30 sets, corresponding welding programs can be recalled according to the specification of welding parts

- The welding seam longitudinal and transverse automatic tracking function, accurate welding positioning, welding process stability

- One key operation, automatic completion of welding process, but also manual intervention.

Model

GW70T

Welding material

Carbon steel, stainless steel

Welding diameter

Ф18mm-Ф70mm

Welding power

Pulse argon arc welding power supply, rated current 440A

Supply power

Welder 30KW/380V/50HZ Controller 1KW/220V/50HZ

Rotate speed

0.3rpm-1.5rpm

Shielding gas

argon

Cooling mode

Water cooling

Controller

Color touch screen controller

Storage

30 sets of welding process

Welding layers

Automatic layering

Arc length tracker

Tracking range0-20mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm

Wire feeder

wire diameter1.0mm

Overall size

760mm*850mm*1400mm

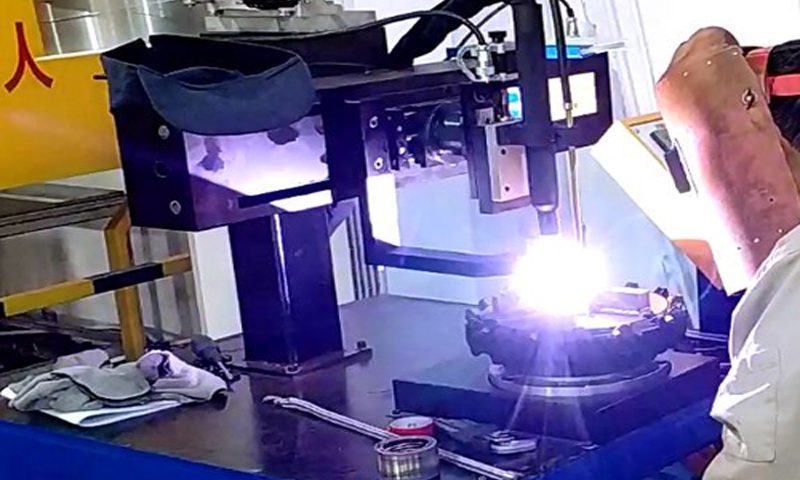

Video

Gallery

Introduction

Welding Machine for Corrugated Metal Pipe/Meshy Sleeve and Commpressing Sleeve

Feature

- Welding torch fixed, chuck clamping drive workpiece rotary welding

- Suitable for the welding of bellows, mesh sets and compression sleeves

- Suitable for carbon steel, low alloy steel, stainless steel and other materials of welding

- Adopt tungsten argon arc welding equipment.

- The whole machine integrated design, compact structure, mature and reliable; Three – jaw self – centering chuck accurate rotation and positioning

- CNC automatic wire feeding machine, with automatic reverse wire drawing function and pulsating wire feeding function, wire feeding precision is high

- Control system adopts touch screen man-machine interface, convenient programming

- The welding program storage is 30 sets, corresponding welding programs can be recalled according to the specification of welding parts

- The welding seam longitudinal and transverse automatic tracking function, accurate welding positioning, welding process stability

- One key operation, automatic completion of welding process, but also manual intervention.

| Model | GW70T |

| Welding material | Carbon steel, stainless steel |

| Welding diameter | Ф18mm-Ф70mm |

| Welding power | Pulse argon arc welding power supply, rated current 440A |

| Supply power | Welder 30KW/380V/50HZ Controller 1KW/220V/50HZ |

| Rotate speed | 0.3rpm-1.5rpm |

| Shielding gas | argon |

| Cooling mode | Water cooling |

| Controller | Color touch screen controller |

| Storage | 30 sets of welding process |

| Welding layers | Automatic layering |

| Arc length tracker | Tracking range0-20mm, Tracking speed0-6mm/s,

Arc length tracking accuracy0.2mm |

| Wire feeder | wire diameter1.0mm |

| Overall size | 760mm*850mm*1400mm |