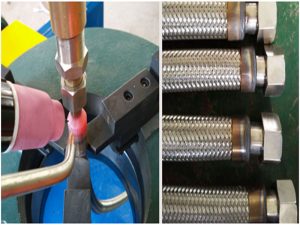

Automatic Metal Hose Joints (Flange) Welding Machine

Automatic welding machine for metal hose joints, welding gun and displacement mechanism can realize flexible angle adjustment, so that the equipment has wide adaptability and can complete the welding of most existing pipe joints such as flanges, elbows and wire heads.

Key points of welding process

1 Key points of metal hose body welding process

(1) Due to the special three-layer structure of the metal hose body and the poor repeatability of pre welding assembly, the welding process must have enough tolerance window.

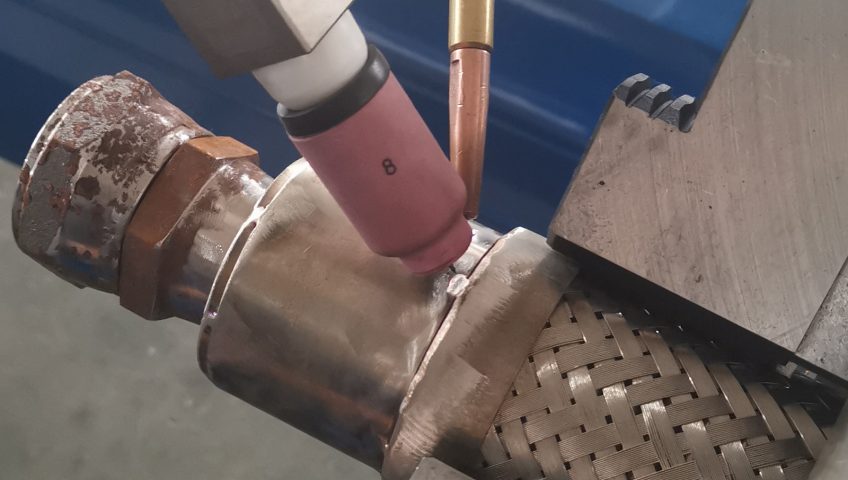

(2) Because thin-walled parts are very sensitive to welding line energy, the welding process requires accurate control of welding current and welding voltage, and must be matched with the amount of wire filling.

2.key points of metal hose joint welding process

Generally specking, the thickness of hose joint and compression pipe sleeve is quite different, and the types of pipe joint are diverse. Therefore, the influence of welding angle on weld formation and quality should be fully considered in the welding process.

Conclusion

- Corrugated metal hose has a wide range of applications and large dosage. Its working temperature range can reach – 196 ℃ ~ + 420 ℃, and the pressure range is generally pN0 6-32.0mpa, up to 42.0mpa, with high weld quality requirements.

- Due to the special multi-layer structure of metal hose, in order to ensure the welding quality, higher requirements are put forward for the butt joint quality before welding, welding process and welding equipment.

- Automaticwelding process are developed for corrugated metal hose welding industry, with high degree of automation, stable process parameter control, strong process adaptability and good practical application effect

-